With a professional development team, advanced design concepts, reliable manufacturing processes, and thoughtful technical support and after-sales service, our company has rapidly grown into a pioneer in the rod drawing machine, barbed wire drawing, Inverted Drawing Machine industry. We are looking forward to becoming one of your most reliable suppliers. To provide customers with better and more timely service is our purpose during cooperation. With facilities for R&D, design, manufacturing, and testing, we provide one-stop solutions that maximize convenience and minimize lead time. Under the premise of ensuring product quality, we continue to increase production and contribute to our customers. Warmly welcome to join us, let's innovation collectively, to flying dream.

Copper wire drawing ![]() Specifications

Specifications

LT9-450Copper Large Pull with continuous annealing production line

copper rod breakdown machine;rod breakdown machine;8mm copper rod dawing machine

From 8mm to 1.78mm—3.30mm

copper rod input diameter:8mm,

output diameter: 1.78mm—3.30mm

production speed:480meters/s

production capacity: 1200KG/hour

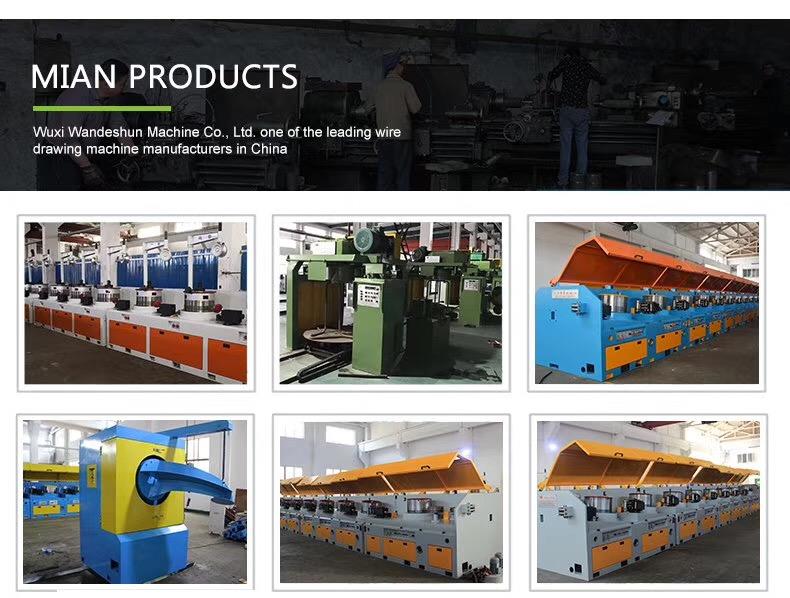

Our Main Products

copper rod breakdown wire drawing machine (450/LT9)

number of dies:9

installed capacity:125KVA (Main motor:AC.110KW,spooler motor:15KW)

drive: frequency inverters

Dimension length 3000 * 1800mm Weight 6.5T width

This company produces LT9-450 continuous annealing line used with pull-plus double-disc received Continuous Annealing Line (or, as the nose unloading line) production model, the formation of the entire production line continuous operation, drawing machine from a copper rod into the line of direct pull 8.00mm Model copper wire.

Annealing mode DC-annealing, annealing the use of advanced low-voltage power supply high current power supply, the control system adopts microcomputer intelligent control, equipment operation more stable, the maximum speed of 8 m / sec.

In the production process, we formulate strict technical procedures and testing requirements to ensure the quality of the Metal Stamping Parts Made as Customer's Drawing. The purpose of the enterprise has cultivated our good corporate image and reputation. In the era of rapid change, we take advantage of leading technology, advocate the future with science and technology.

Hot Tags: brass wire drawing machine/copper wire drawing, China, manufacturers, suppliers, factory, made in China, wire drawing machine hyderabad, notebook other products, low carbon straight type wire drawing machine, common wire nail making machine, Straight Type Wire Drawing Machine, Wet Wire Machine