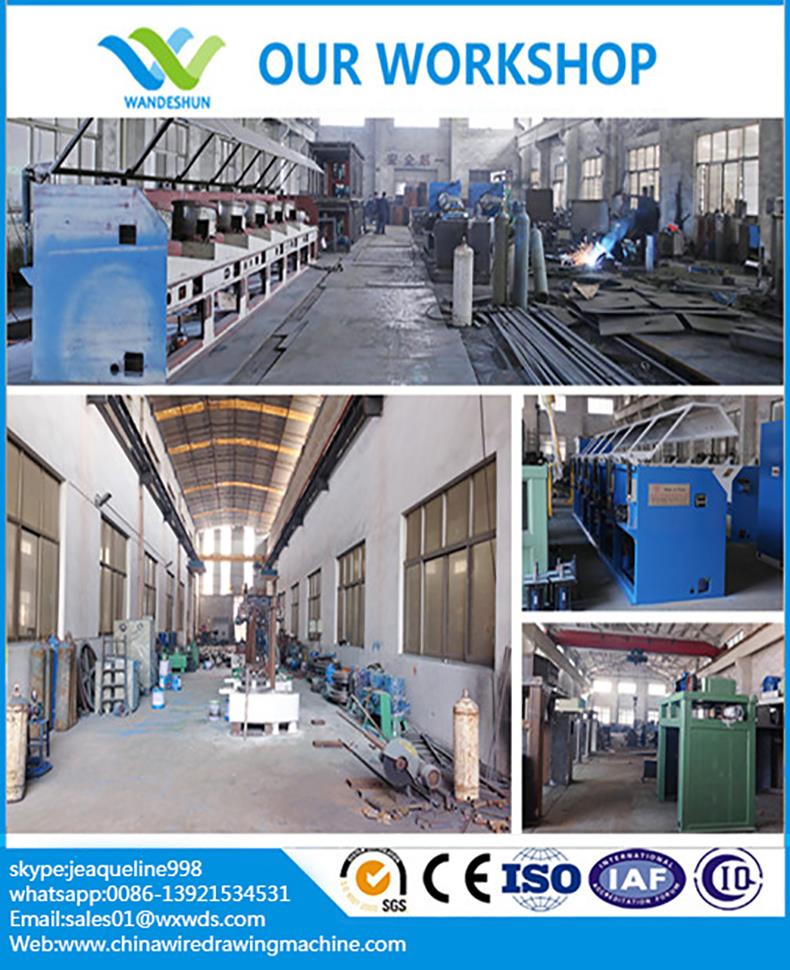

We are a newly rising star in the field of wire drawing drum, used wire cutting machine, wire pointing machine, with rapid business development. We believe in 'create a company with integrity, promote a brand with quality, and develop the future with diligence'. With the rapid development of economy in the new century, all the staff of our company will continue to explore and innovate, further improve the quality of products.

Our inverted wertical drawing machine at the production site of Changshu Standard Parts Plant | ||

Main Technical Parameters | ||

Items | Unit | Model |

Diameter of capstan | mm | 550- 1400 |

Maximum diameter of inlet wire | mm | 40 |

Intensity of material | Mpa | ≤1200 |

Compression rate | % | 15-30 |

Maximum drawing speed | m/s | 2.5 |

Motor power | kw | 11-110 |

The product is developed for the non-slip drawing of medium & low carbon steel wire, special shaped steel wire and nonferrous metals with thick & medium diameters.It is especially suitable for the drawing of medium & low carbon steel wire in standard parts and supermarket shelf industry.The maximum inlet diameter can reach 30mm and diameter of capstan is 550-1330mm.

Transmission part of the system can apply cycloidal speed reducer,harden gear surface reducer orrockerreducer.Its electric system applies international famous brand frequency converter with stable

performanc. Features of the equipment

1.It is applicable for continous production process of coil with heavy charging box.

2.Easy operation and reliable control enables safe production and convenient maintenance.

3.Application of 3-phase AC variable-frequency speed adjustment realizes smooth stepless speed regulation and saves more than 30% electric power.

Full automatic feeding+ automatic cutting+ inverted drawing machine production line is the special equipment for the market by our company’s digestion and absorption of foreign advanced technology and design of heavy wire, large diameter drawing, simple and reliable operation, high safety. Unique high performance, humanization design is the preferred equipment drawing of low carbon wire rod, widely used in metal products, raw silk, bolt of large diameter wire drawing industry, deeply loved by industry experts and entrepreneurs who have farsightedness.

Characteristic instruction

★ the wire feeding with programmable frequency conversion control, makes the stability which linkage of wire drawing machine is very high, the design of multiple safety protection device for production safety equipment, so the equipment can be more stable operation, safe and reliable. Wire feeding process is fully automatic, without manual operation.

★ cutting mechanism of control is the same with the wire feeding machine, driven by hydraulic control, the operation is convenient and flexible, automatic cutting process, the cutting effect is excellent.。

★ the control of inverted drawing machine is safe operation mode, stop immediately for emergency shutdown, tangled lines, break and electrical faults, the brake system is safe and reliable, the operation is convenient and flexible, humanized design makes the whole line operation more convenient and reliable, the entire line of the main electrical components, hydraulic components are equipped with international famous brand products.

Automatic wire feeding part | Automatic cutting part | The inverted drawing part | ||||||

name | unit | parameter | name | unit | parameter | name | unit | parameter |

The active roller diameter | mm | Φ250 | Cutting mode | Built-in rotary cutting | Drum diameter | mm | Φ550-1500 | |

speed | m/min | ≤50 | Cutting process | automatic | The largest diameter line | mm | Φ38 | |

Motor power | Kw | 5.5-11 | Motor power | Kw | 0.75-1.1 | Inline strength | Mpa | ≤1200 |

Feeding style | Single action, linkage | The mobile form | Hydraulic, hand, automatic control | compression ratio | % | 15-30 | ||

Press wheel form | Adjustable hydraulic control | gearbox | Cycloidal needle wheel | The max wire drawing speed | m/s | 0.5-2.5 | ||

gearbox | Double gear drive | Cutting diameter | mm | Φ12-38 | Motor power | Kw | 22-110 | |

Wire diameter | mm | Φ12-38 | Cutting material strength | Mpa | ≤1000 | Control mode | AC variable frequency speed regulation | |

Material strength | Mpa | ≤1000 | Control mode | PLCcontrol | Reduction box | Hardened face gear drive | ||

Control mode | PLC control | |||||||

Should you're in need of quality and stable inverted vertical wire drawing machine for making bolts/screws/spring made in China, welcome to buy the machine from our factory. We are one of the leading such manufacturers and suppliers in China, equipped with advanced equipment and technology. Welcome to contact us.

We have been committed to offering easy, time-saving and money-saving one-stop purchasing service of consumer for Large Caliber PE Thermal Insulation Pipes Extrusion Line. The tenet of our company: honesty is the cornerstone, quality is the guarantee and win-win is the goal. Our company takes 'let customers get value-added service' as the guiding business philosophy of the company's development, and has the products of real value and complete varieties.

Hot Tags: inverted vertical wire drawing machine for making bolts/screws/spring, China, manufacturers, suppliers, factory, made in China, automatic steel wire cutting machine, automatic wire cutting machine, Pulley Type Dry Wire Drawing Machine, drawn wire, stainless steel wire drawing line, Wet Wire Drawing Machine for Fine Wires