In the future, we will try to use new technology to create new business value and to contribute to research and product development for the wire drawing technology, high carbon Steel Wire Drawing Machine, low carbon wire drawing machines. We hope to affix hands with mates in different industries to make a excellent future. We adhere to honesty and great faith operating attitude, looking ahead on your coming! Only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment.

Copper wire drawing ![]() Specifications

Specifications

LT9-450Copper Large Pull with continuous annealing production line

copper rod breakdown machine;rod breakdown machine;8mm copper rod dawing machine

From 8mm to 1.78mm—3.30mm

copper rod input diameter:8mm,

output diameter: 1.78mm—3.30mm

production speed:480meters/s

production capacity: 1200KG/hour

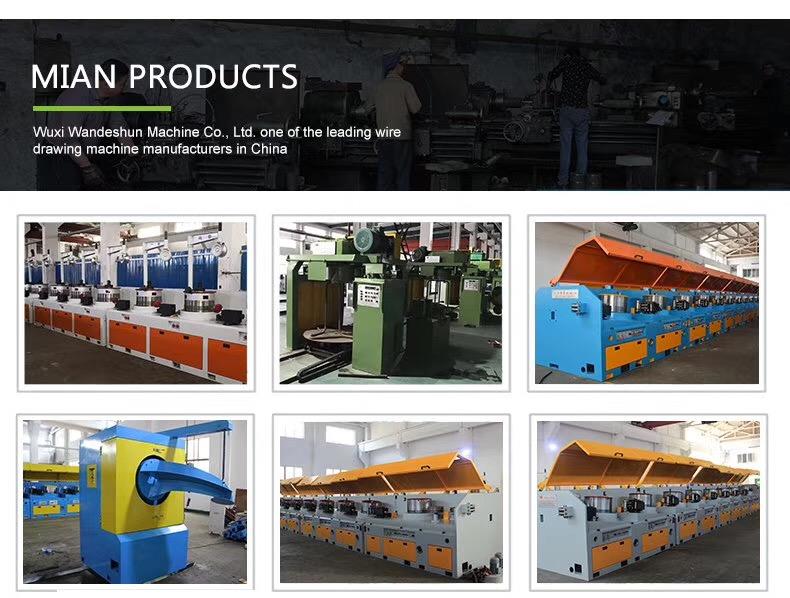

Our Main Products

copper rod breakdown wire drawing machine (450/LT9)

number of dies:9

installed capacity:125KVA (Main motor:AC.110KW,spooler motor:15KW)

drive: frequency inverters

Dimension length 3000 * 1800mm Weight 6.5T width

This company produces LT9-450 continuous annealing line used with pull-plus double-disc received Continuous Annealing Line (or, as the nose unloading line) production model, the formation of the entire production line continuous operation, drawing machine from a copper rod into the line of direct pull 8.00mm Model copper wire.

Annealing mode DC-annealing, annealing the use of advanced low-voltage power supply high current power supply, the control system adopts microcomputer intelligent control, equipment operation more stable, the maximum speed of 8 m / sec.

Our raw materials are carefully selected in line with the supremacy of the customers, and wholeheartedly provide customers with quality Customized Precision Parts High Quality CNC Machine Spare Grinding Processing CNC Turning Processing Wire EDM Cutting Processing Automatic Lathe Machnical Parts. We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. We establish a sustainable and good brand image of the company.

Hot Tags: brass wire drawing machine/copper wire drawing, China, manufacturers, suppliers, factory, made in China, Turnover wet wire drawing machine, metal wire drawing, Horizontal wire drawing machine, Welding wire drawing mach, wire drawing plant, Drawing machine