We believe in long expression and trusted relationship for Wire Drawing Machine technological process, iron nail making machine, Welding wire drawing mach. We pursue perfection in every detail and carry out strict quality control on every process. Our company adhere to the business philosophy of 'integrity and pragmatic, winning by quality' to continuously improve quality management system to a higher goal for ourselves. We have a good tracking service, and continuously rising sales. Warmly welcome to cooperate and develop with us!

Copper wire drawing ![]() Specifications

Specifications

LT9-450Copper Large Pull with continuous annealing production line

copper rod breakdown machine;rod breakdown machine;8mm copper rod dawing machine

From 8mm to 1.78mm—3.30mm

copper rod input diameter:8mm,

output diameter: 1.78mm—3.30mm

production speed:480meters/s

production capacity: 1200KG/hour

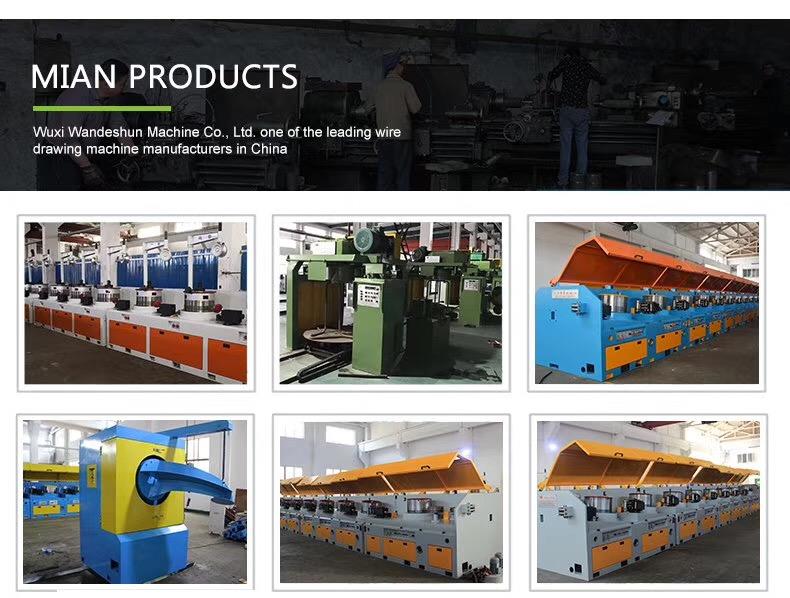

Our Main Products

copper rod breakdown wire drawing machine (450/LT9)

number of dies:9

installed capacity:125KVA (Main motor:AC.110KW,spooler motor:15KW)

drive: frequency inverters

Dimension length 3000 * 1800mm Weight 6.5T width

This company produces LT9-450 continuous annealing line used with pull-plus double-disc received Continuous Annealing Line (or, as the nose unloading line) production model, the formation of the entire production line continuous operation, drawing machine from a copper rod into the line of direct pull 8.00mm Model copper wire.

Annealing mode DC-annealing, annealing the use of advanced low-voltage power supply high current power supply, the control system adopts microcomputer intelligent control, equipment operation more stable, the maximum speed of 8 m / sec.

We are committed to providing customized Carbide Wear Parts as Drawing solutions to global users. With strong company strength, excellent product quality and perfect after-sales service, our products are well-received by domestic and foreign customers. Creating a high-quality brand and building a century-old enterprise is our goal, and we will continue to serve our customers with talents, technology and products. All along, we adhere to the customer-oriented, market-oriented, constantly improve product quality and develop product types to meet the growing needs of customers.

Hot Tags: brass wire drawing machine/copper wire drawing, China, manufacturers, suppliers, factory, made in China, wire bunching machine, Pulley Type Dry Wire Drawing Machine, Single Chain Drawing Machine, wire drawing process step by step, koch wire drawing machine germany, Welded wire mesh machine