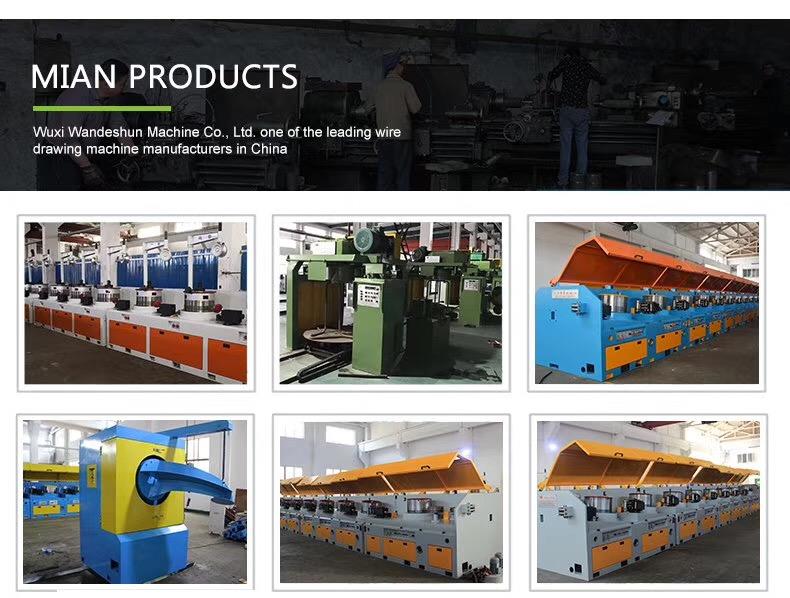

With strong strength and excellent quality assurance, our company is gradually developing into China's most powerful roller die wire drawing machine, Pulley Type Mild Steel Wire drawing, copper wire stripping machine brand with great momentum. We focus on good cooperation with our customers, we hope to have long-term and stable business contacts and achieve a good situation of mutual win and mutual benefit between the two aspects. Our supply is large, for the sales scope spans through various domestic and oversea regions.

Copper wire drawing ![]() Specifications

Specifications

LT9-450Copper Large Pull with continuous annealing production line

copper rod breakdown machine;rod breakdown machine;8mm copper rod dawing machine

From 8mm to 1.78mm—3.30mm

copper rod input diameter:8mm,

output diameter: 1.78mm—3.30mm

production speed:480meters/s

production capacity: 1200KG/hour

Our Main Products

copper rod breakdown wire drawing machine (450/LT9)

number of dies:9

installed capacity:125KVA (Main motor:AC.110KW,spooler motor:15KW)

drive: frequency inverters

Dimension length 3000 * 1800mm Weight 6.5T width

This company produces LT9-450 continuous annealing line used with pull-plus double-disc received Continuous Annealing Line (or, as the nose unloading line) production model, the formation of the entire production line continuous operation, drawing machine from a copper rod into the line of direct pull 8.00mm Model copper wire.

Annealing mode DC-annealing, annealing the use of advanced low-voltage power supply high current power supply, the control system adopts microcomputer intelligent control, equipment operation more stable, the maximum speed of 8 m / sec.

We struggle for creating an environment conducive to innovation activities, to enhance our innovation capabilities, and thereby increase the added value of our Anodized Titanium Circle Parts CNC Custom Machined. We hope to win a resplendent future for customers and ourselves. Our company will adhere to the principle of technological innovation, management innovation, concept innovation and development idea innovation.

Hot Tags: brass wire drawing machine/copper wire drawing, China, manufacturers, suppliers, factory, made in China, dry steel wire drawing machine, wire drawing machines south africa, Bar Straightening and Cutting Machine, automatic cutting machine, steel nail making machine, Electric Wire Production Line